Intern Kevin is helping to close a gap in available sensors

Absolute inductive encoders can be used as distance sensors, but their availability is limited for measurements of more than one meter. Together with R&D engineer David Reuijl, the University of Applied Sciences students Yordie Timmerman and Kevin Vos have developed an absolute long-stroke encoder that is suitable for measuring larger distances with great accuracy.

Many of Sentech’s customers opt for an absolute encoder when they need to measure distances accurately. Whether magnetic, inductive, capacitive or, since recently, also optic — the range of technologies is diverse. But larger systems have a key limitation: distances of more than one meter are to all intents and purposes feasible only using encoders based on magnetism. However, these encoders usually cannot be utilized because they function poorly in proximity to the magnetic field from, for example, a nearby linear motor. There are indeed non-magnetic solutions on the market that extend further than a meter, but they are clumsy and expensive. These are not realistic options for many mechanical engineers.

David Reuijl, R&D engineer at Sentech, identified that gap in the sensor product range and started investigating. Would it be possible to develop an affordable inductive encoder that can register longer distances without any problems? The need for such a system became evident 18 months ago, when a case arose in which such a long-stroke encoder would have provided the solution. Specifically, the customer was looking for a solution that could accurately position its pick-and-place delta robot over longer distances.

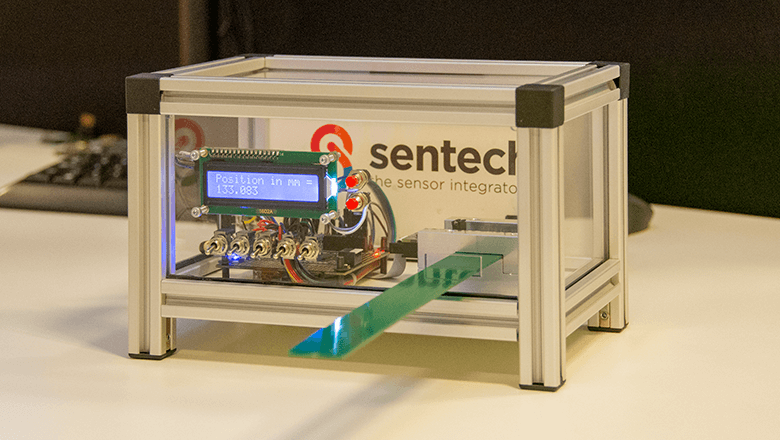

David got straight to work. Together with intern Yordie Timmerman from the Fontys University of Applied Sciences, David designed a first proof of concept. At the core of the system is a ruler with four parallel tracks. The pitch of each track is slightly different, which results in a unique set of four measured values at every ruler position, and these measured values can be converted to an absolute distance. Using an algorithm, the four encoder signals are converted into an absolute position value within a range of more than one meter.

Vernier scale and barcodes

To understand the operation of what Sentech calls the long-stroke encoder, we must zoom in on the phrase ‘vernier scale.’ That term is best explained using a vernier caliper. Suppose you read on the main scale there that a certain thickness is between, say, 13 and 14 millimeters. Of course, you could estimate whether it is 13.7 or 13.8 mm but it’s more accurate to look at the secondary ruler on the vernier caliper — the vernier scale — which tells you that the thickness is, for example, 13.7 mm.

The long-stroke vernier scale encoder from Sentech works in a similar manner — but the other way round. What this amounts to is that the first track gives a value, say 0.05 cm. The second track tells you that you are measuring between 0.7 and 0.8 cm. The third track indicates that it concerns the section of 3 to 4 cm. And, finally, the fourth track says that the position lies between 10 and 20 cm. The final measurement is therefore 13.75 cm.

The reality, in fact, is somewhat more complicated than this decimal simplification. The bars on the first track are 1.2 mm apart. The pitch of the second track has been selected so that it overlaps the first track again after sixteen steps on the first track (so, after 19.2 mm). This means that the encoder system can read off, from the second barcode pattern, in which of the first track’s sixteen sections it is performing the measurement. But which 19.2-mm section of the entire ruler is it? This becomes clearer by looking at the third track. Its pitch is again in line with the first track after 16 x 16 steps (so, after 307.2 mm). And, you guessed it: the fourth track requires 16 x 16 x 16 times 1.2 mm (so, 4915.2 mm) to be in step and say in which section of 307.2 mm you are measuring.

FPGA

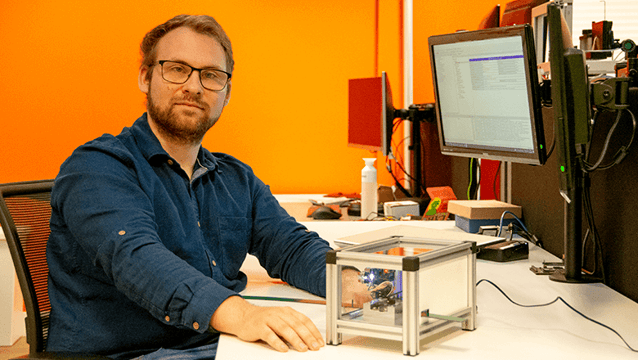

The first encoder version demonstrated that the principle worked, albeit with aspects in need of improvement. For example, there was some mechanical play in the system that influenced the accuracy. “And we ran up against the limits of the encoders,” says Kevin Vos, an intern from the Fontys University of Applied Sciences, who is involved in the second phase of the research project. “Those encoders have a maximum refresh rate and then have to wait 100 milliseconds before they can load the next word.”

The solution was to replace the microcontroller that was originally selected with a Field Programmable Gate Array (FPGA) controller from Lattice Semiconductor. “After all, the encoder signals in the first system also had to wait for each other,” says Kevin. Because a microcontroller works sequentially, there was quite a time difference between the results of the four tracks. “With an FPGA, you can process the four signals in parallel and then immediately perform a calculation on them. This means the outcomes are available simultaneously so that you can determine an accurate absolute position, even at high speeds. We are currently achieving a resolution of 73 nanometers.”

Industrialization

Kevin’s half-year internship is coming to an end. “Now, I’m busy conducting the final tests,” he explains. “We would like to accurately identify what the specifications of the system are and what we can guarantee.”

But that doesn’t mean the encoder system is ready for market, even though Kevin, together with David, is already taking the first steps toward industrialization. According to Kevin, “We’re looking at how we can realize it in a more robust and more cost-efficient manner.” That could be done, for example, by selecting a cheaper FPGA from Lattice. “The price of the system was not an issue up to now, but if Sentech wants to market it soon we will have to pay attention to that, of course. At the same time, we are researching the ability to connect multiple encoder heads on the same FPGA.”

Another item to be addressed is the ruler. Due to practical considerations, the ruler is currently only half a meter in length. “This enabled us to easily take the system home during the coronavirus period,” Kevin chuckles. The ruler did not have to be longer to demonstrate the principle. But if the system wants to soon register distances up to five meters, then naturally the ruler will have to be long enough. “At the moment we are still using PCB material, which can readily be made into something just over a meter in length. For longer lengths, we will probably have to look at other materials and production methods. We do have some ideas already, but that is still a work-in-progress. I will leave that up to David, and maybe to the next intern.”

Mechatronics intern arranged within one week

In his third year at the Fontys University of Applied Sciences in Eindhoven, mechatronics student Kevin Vos was looking for an internship. “It was the middle of the coronavirus pandemic. Because of all the lockdowns and limitations, few companies dared to bring an intern in-house,” Kevin relates. He followed an online company presentation, and was happy with what he saw. “I sent an email to Danciëlle Megens in HR. I received a response the same day and everything was arranged within one week.” Kevin’s first project at Sentech was about a so-called Wiegand encoder that can generate its own energy.

In his fourth year at Fontys, Kevin was once again looking for an internship and he again found a nice assignment at Sentech. “I had just done a project about FPGAs and encoders. That was the perfect introduction for the long-stroke vernier scale encoder, where the microcontroller had to be replaced with an FPGA,” says Kevin.

Want to see more sensor technology?

Wild, isn’t it?! How a technological solution like that is developed from the ground up based on a need. This is what we do all the time in our R&D department. This means that our internship assignments are not your standard run-of-the-mill internship assignments. You work with cool sensor technologies that actually have a specific purpose.

Are you curious whether there are any internship or graduation opportunities right now? Or would you just like to come and take a look at what we’re up to?

Then drop by for a cup of coffee. We would be happy to give you a tour of our location. Send a quick message to Linsey.