Absolute encoders with ultimate integration possibilities

When integrating absolute encoders, you as an OEM or mechanical engineer test the limits of the catalog products. Unfortunately, those off-the-shelf components often turn out to be unsuitable for your application. For example, either they are too heavy or they have the wrong construction form. Sensor manufacturers are aware of this — and they are responding to this need.

Increasingly, the available features in such a component form the stumbling block. Some include options that developers are not exactly looking for, while the functionality that can make a difference is nowhere to be seen.

Sensor manufacturers are responding to this trend. They are bringing stripped-down versions of their products on the market. They are returning to the foundation of their solutions. The functionality of the sensors withstands all scrutiny, but the remaining features have been scrapped. What is left is just bare electronics.

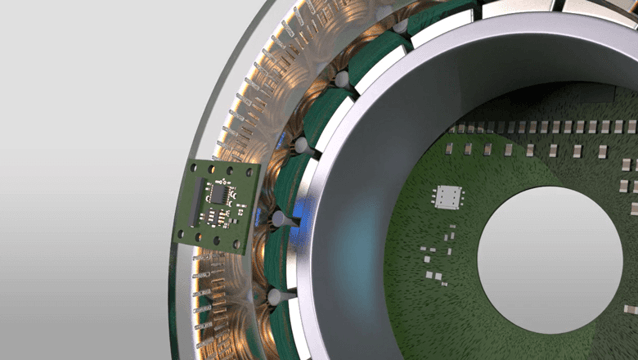

A machine developer or sensor integrator can construct a shell around these bare electronics according to their own wishes and insights. A component such as this requires more attention when it comes to integration — but then it has been completely customized for the application. The result is a more compact and lighter solution, which is interesting for spots where space is limited or where weight plays an important role.

A component that was previously only available in a robust aluminum housing, for example, is now also available in a stripped variant. Such a bare sensor consists of a small printed circuit board or even a single component that the user can place on a PCB. The full functionality remains intact, while all peripheral matters are gone, which enables such a version to form the basis for very many ancillary applications.

Celera Motion launched a series of absolute optical encoders with a focus on flexibility. The Aura chip encoders are stripped of all peripheral matters without compromising the cleverness of the sensors. Users can select the features they want to add and therefore fully customize the encoder for their specific application.

Easy-to-integrate absolute encoder due to minimalistic design

A good example of this development is the Aura line of encoders from Celera Motion. All the versions in this series of absolute encoders have a minimalistic design. “They are chip encoders — PCB components that you can integrate into your own design”, says Rob Kuijpers, Product Manager at Sentech. “This is very interesting for OEMs because these encoders are very versatile. OEMs do have to make more of an effort for this. But they can implement it exactly as they like, which allows them to construct the encoder system in such a way that it precisely fits their specific application.”

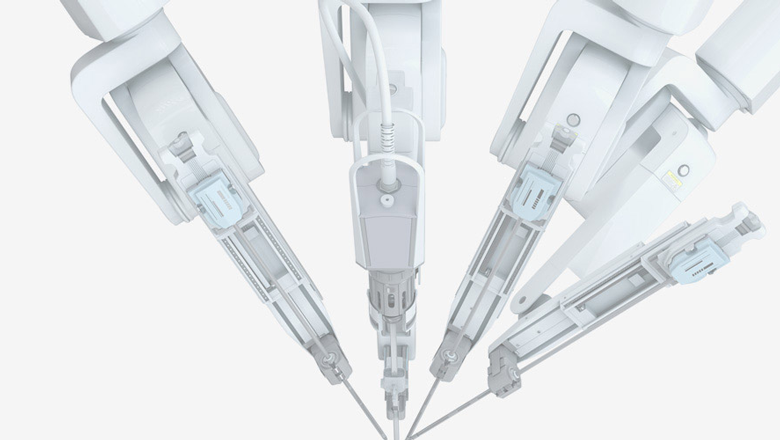

The Aura encoders are very suitable for applications in the high-tech market, in high-end robotics, and in pick-and-place machines, among other uses. “Some examples are applications where the sensor must be extremely small or where the weight of the sensor is vitally important, such as when it is located in an end effector”, clarifies Kuijpers. “And we're talking about situations where optical encoders must give a very accurate absolute position value.”

Optical miniature encoder

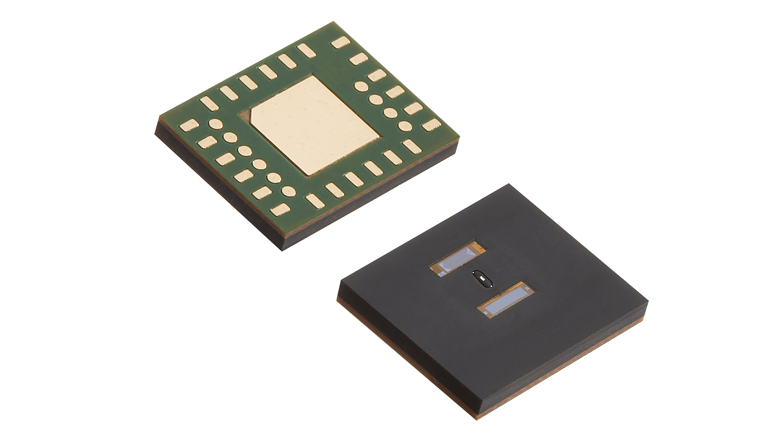

The Aura's are not the first absolute optical encoders on the market. Current solutions are significantly larger and more expensive. The chip encoders from Celera Motion are very small (9 x 7 x 1.1 mm), feather-light (about 1.5 grams), and significantly less expensive.

Because of their optical character, note that the encoders are best utilized in environments that are relatively clean. After all, contamination and moisture spell disaster for a measurement that must be of the utmost precision.

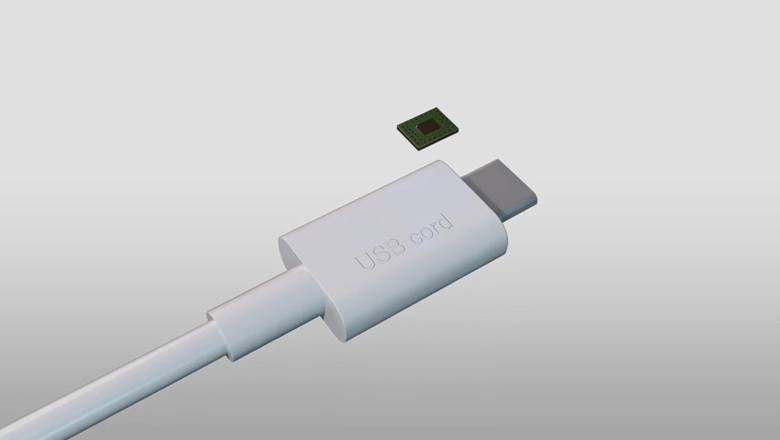

How big is such a chip encoder? This Aura chip encoder is 9 by 7 by 1.1 mm. This is how the proportions are compared to a USB-C connector.

Absolute position value

The Aura encoders use a LED as light source. The light of the LED in the Aura is blue, and that was a conscious choice. The shorter the wavelength, the smaller the details that you can distinguish with it. This allows the Celera Motion absolute encoders to perform better.

The bundle falls on a pattern of chrome stripes that are deposited on glass. The reflection of the light on all those stripes produces a diffraction pattern that you can read with a receiver. “There are two of those stripe patterns in the Aura encoders”, states Kuijpers. “One is neatly repeated, and the other is semi-random. By combining the two diffraction patterns, the system can calculate an absolute position value.”

How accurate are Aura encoders?

Precisely how good the Aura encoders are cannot be expressed in just one number. Mostly, three key specifications are reviewed: absolute accuracy, repeat accuracy and resolution.

Absolute accuracy

“That first specification is determined by the ruler that you use”, says Kuijpers. Celera Motion has opted for a glass scale with an accuracy of +/-3 µm per meter. The manufacturer is working on a variant based on a metal tape scale. With its +/- 5 µm per meter, that is less accurate but quite a bit less expensive and therefore interesting for applications that don't have to offer everything in terms of accuracy.”

Repeat accuracy

According to the specifications sheet, the repeat accuracy of the Aura encoders is 1 LSB, which stands for least significant bit. Kuijpers explains: “The value depends on the resolution of the encoder. In this case, the repeat accuracy agrees with the smallest resolution step.”

Resolution

Celera Motion indicates the Aura's resolution is a value between 12.5 and 200 nanometers. Kuijpers adds, “You'll get a resolution of less than a micrometer, in any case. What's more, a great advantage of the Aura encoders is that they are very fast. So, you can quickly sample, which means you can average multiple measurements - without too many negative side effects - in order to improve the resolution.”

New approach to integration

Integrating the Aura encoders involves more time and effort than what is needed for a standard sensor. “It requires a new view of integration. This approach fits well with our way of working, in which we, together with our customers, look for the best implementation and connections”, states Kuijpers. “In consultation, we look at which variations, features and cabling we will add. That ultimate flexibility opens a lot of doors.”

Step-by-step plan: How do you integrate an absolute encoder?

There's a lot to pay attention to in the integration of a sensor such as an absolute encoder. How do you find the overview? And how do you balance the compromise between quality, price, and turnaround time?

We make it easy for you. You'll find the proven working method for sensor integration in our handy infographic. Did you know that this working method is based on the high quality standards used in the automobile industry?

Don't wait to download this infographic. In five phases, you'll learn how to develop your own sensor integration step by step.