Linear encoders: which technology do you need?

The first question to ask yourself when looking for a suitable linear encoder is: Do I need to know the absolute position, or is detecting incremental position changes sufficient?

Until recently, incremental solutions were generally favored, but that is changing. Absolute encoders are increasingly being seen as the preferred option.

Absolute encoders always know their position without the need for homing. This means that the machine will start up quickly. An absolute encoder also allows the machine to continue where it left off in the event of unforeseen circumstances such as a power outage. This reduces the chance of failure to a minimum.

Not every sensor technology allows for the simple addition of absolute measurement to the encoder. Most of our capacitive encoders have the cost-efficient absolute measurement option available.

Which technology is best?

Four main technological solutions are used for linear encoders: optical, inductive, magnetic and capacitive. The way they work is essentially the same. A transmitter sends a signal or a field to a scale with a repeating pattern that changes that signal. A receiver detects this change, and uses the sinusoidal variation to calculate how many steps on the scale have been passed.

Optical encoders

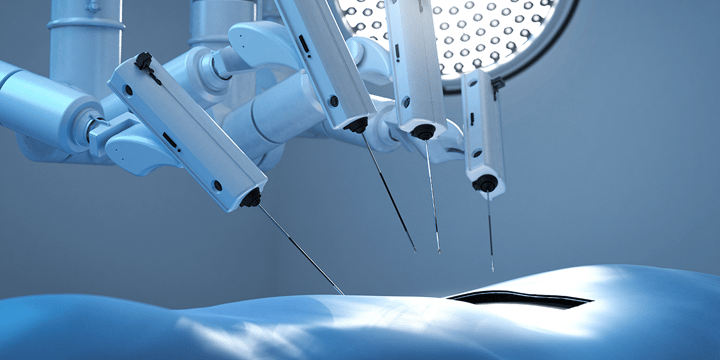

Optical encoders are popular. They use an LED or a laser as an emitter, and are ideal for the high-tech market. An etched stripe pattern reflects the light, then the receiver detects the variation in intensity. An LED encoder is cheaper than the laser version, but it does require a lens to converge the beam, so it is slightly larger. Optical encoders are very high resolution,

and can detect steps down to the nanometer. The encoders themselves are also very small. Modern versions the size of a microchip are available, about 6 by 6 millimeters. This makes them easy to integrate into your design, and offers plenty of potential in areas such as medical robotics. They are suitable for use in vacuums and insensitive to electromagnetic fields, but they are less resistant to contaminants such as dust and moisture. If the distance between the sensor and the scale varies considerably, it is also better to use a different method.

Inductive encoders

Inductive encoders use two coils and a scale with copper strips that affect the field of the transmitter coil. There is a limit to how accurately these strips can be placed, so these encoders are unable to achieve the same resolution as optical versions. However, an accuracy of a few micrometers is more than enough for many applications.

Inductive encoders are resistant to a greater variation in reading height and contamination, and are considerably cheaper than optical encoders.

'Encoders such as this inductive encoder consist of two parts: the ruler (linear or rotary) and an encoder head.

Magnetic encoders

The scale in a magnetic encoder consists of alternating north and south poles. The pitch, which is the basis of the accuracy, is relatively large, so these encoders are not particularly accurate, but are excellent at dealing with changes in motion. The accuracy of the movement over the scale is much less critical than with optical encoders, and even less so than with inductive encoders.

One disadvantage is that they need quite a bit of electronics, which makes them unsuitable for use in a vacuum where they are unable to dissipate heat and can end up burning out. As you may expect, magnetic encoders will also not work properly near permanent magnets or motors.

Capacitive encoders

A capacitive encoder builds an electric field between two elements. The moving element affects the capacitance of this system, allowing for accurate position determination. Capacitive encoders offer high resolution and accurate position measurement up to 1 μm. They are impervious to contamination such as dust, oil, and other organic materials. They are also unaffected by magnetic fields. However, this type of encoder is sensitive to moisture. The relatively high installation tolerances make it easy to incorporate capacitive encoders and they are insensitive to vibration.

Comparison of 4 encoder technologies

What features should you look for in your choice of technology? Use this infographic to compare capacitive, optical, inductive and magnetic (MR) encoders.

Whitepaper

All about capacitive linear encoders. Compare them with other technologies. And discover technical specs.

download PDF