Long stroke encoder: measure long distances of up to 5 meters

Optical encoders are ideal for measuring positions, and consequently distances, very precisely, but their range is generally limited to around 0.5 meters. At Sentech, we’ve been working for some time on an absolute encoder system with a range of almost 5 meters. If you want to avoid any compromises when integrating an encoder in your application, check if our long-stroke vernier encoder can help you further.

If you need to accurately determine a longitudinal position, an encoder is the obvious choice. There are plenty of market options available for strokes of up to about 0.5 meters, including magnetic, optical, inductive, and capacitive solutions. However, if you want to determine longer distances, the range of options becomes very limited.

There are a few solutions available, but they all have one or more disadvantages; they are expensive, often too slow for most applications, simply not accurate enough, and/or offer little resistance to environmental influences. For example, some absolute magnetic encoders can perform measurements over longer strokes, but they are quite expensive and can’t be used in certain places, such as near a linear motor.

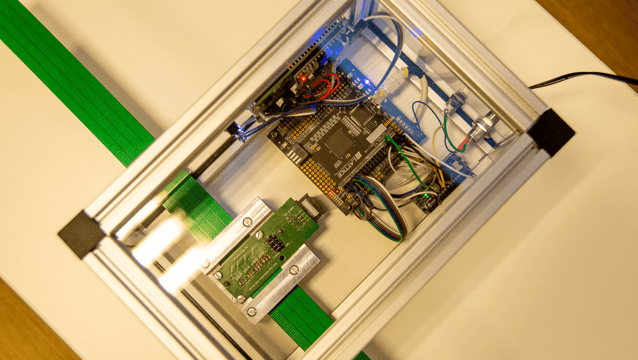

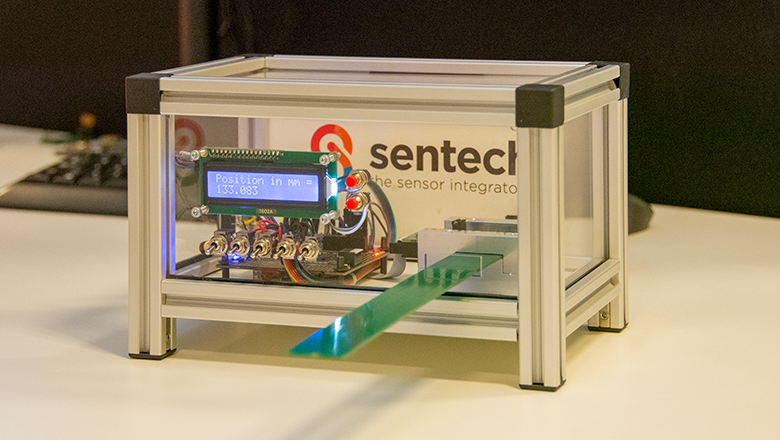

Isn’t there a better way? Can't we devise an absolute encoder with a range of more than half a meter? These were the questions we asked ourselves at Sentech, as our R&D engineers got to work. It all kicked off with two brilliant student projects. Here, two University of Applied Sciences students and R&D engineer David Reuijl laid the foundations for an inductive solution that calculates an absolute position value over a length of up to 4.9 meters.

The University of Applied Sciences students Kevin Vos and Yordie Timmerman have developed an absolute long-stroke encoder that is suitable for measuring larger distances with great accuracy.

Vernier scale: the pros and cons

The system works on the basis of a vernier scale, which you’ve probably come across on old-fashioned vernier calipers. On the main scale, you can accurately read the thickness to the millimeter. while on the second scale, the vernier, the measurement accuracy increases to 0.1 mm.

The disadvantage of a vernier scale is that it has a limited number of distinct positions or measurements it can accurately represent. There comes a point where the unique positions on the vernier scale no longer align with the main scale. For the long-stroke encoder, we therefore had to print no less than four vernier scales next to each other on a ruler. This allows unique combinations of up to 4.9152 meters, and measurements of absolute length up to this entire distance.

In theory a fifth scale could be added to measure even greater distances. 'However,' says Rob Kuijpers, Product Manager at Sentech, ‘the 4.9 meters we can now achieve is already over-engineered for most applications, and in any case it’s extremely difficult to make an accurate ruler that is much longer.'

No more concessions

Sentech’s long-stroke vernier encoder is mainly targeted at applications that require the measurement of an absolute length position between roughly 0.5 and 1.5 meters. 'This is where we expect the most demand,' says Kuijpers. Applications include pick-and-place machines, XYZ stages, grippers, 3D printers, handling robots, greenhouse automation, and so on.

Kuijpers admits that the search is on for the right applications, because very often an incremental system is good enough, or measurement challenges can be solved with a combination of an incremental encoder for the larger strokes and an absolute encoder for the smaller movements. 'Our solution is unique, so engineers are often unaware it exists and will still look for an alternative method. However, if they're having to make compromises over those longer distances but would like a full absolute solution and all its associated advantages, we’re now offering this option.’

The disadvantage of incremental encoders is that they have to be recalibrated after rebooting or a power failure. 'It's better, and sometimes even necessary, if you can skip that step,' says Kuijpers.

Robust and cheaper

Sentech decided to use inductive encoder technology because it’s insensitive to environmental factors. Optical encoders can quickly become dirty, so they often require special shields. In addition, the manufacturing and shipping costs of an optical scale increase exponentially as it gets longer. As mentioned, encoders based on magnetism don’t work well when close to other magnets and metal. An inductive encoder is therefore the most robust and economical solution. Remember, however, that this system is unique, so it’s more expensive than standard inductive encoders.

A housing is usually unnecessary for the long-stroke vernier encoder, but Sentech can easily develop a more robust housing if the application requires it. We can also take into account applications with challenging temperatures, and provide tailor-made solutions which can cope with them (-20 to +100 ºC is possible) and other requirements such as low masses and mass inertias, low wear, high speeds and fast movements, and challenging shapes such as a very flat design.

Does your application require a long-stroke encoder?

Our long-stroke vernier is the result of a search for a solution for absolute length measurements in multiple directions. The advantage is that the data from multiple encoders and scales can be linked to a single controller, which is cheaper and shortens the installation time. That could be an interesting solution for XYZ stages or 3D printers, for example. We don't see any obstacles preventing this.

At the moment, we’re still focusing on absolute length positions in one direction, because, as Kuijpers said, longer distances are a niche market. ‘Not many applications will need it,’ he says, speaking from experience. ‘However, if you actually need it because it’s the perfect solution to your problem, do get in touch. We’d be delighted to develop our R&D project into a ready-made product that meets the wishes of the market. With the knowledge we’ve acquired recently, we can turn your use case into a success.'

If you’d like to know if the long-stroke encoder is suitable for your application, send Rob an e-mail, and he’ll be happy to assist.