Working in the high tech: a working week as a Project Engineer

Johan van den Biggelaar and Ivo van Damme are Senior Project Engineers at Sentech. They will tell you all about their work week. Since they are currently working on fifteen sensor projects, every workday is unique – from sharing technical knowledge on customer visits to dealing with challenging sensor engineering issues. This variety makes working in the high-tech sector so fascinating.

When tackling sensor issues, the Research, Development, and Engineering (RD&E) department also involves other disciplines in addition to the Engineering department. This approach allows our sensor experts to select the right technology in an efficient manner. Let’s take a look at our Engineers’ work week.

Monday: daily meetings

Johan calls into the sales meeting every workday at 8:44 am. “During this short meeting, our Account Managers discuss scheduled customer visits, quotations that need to be developed, and new business opportunities. I am able to directly answer any questions about ongoing projects,” says Johan.

Ivo joins the daily start-of-day meeting at 9:05 am. One person each from the Purchasing, Sales, Production, Logistics, Quality, Planning and Engineering departments is always present. Ivo explains: “Everyone can share any obstacles they are facing. For example, it could be that a delivery date has passed or there is a production delay. If it impacts the process, we work together to find a solution that will limit the impact.”

Johan adds, “We also have a short meeting in our own department. We discuss the points needing attention that were noted at 8:44 and 9:05 am. All of our engineers bring us up to date on their projects and indicate whether they need assistance.”

Sharing technical knowledge

After the start-of-day meeting, Ivo and one of our Account Managers visit a potential customer. “Our Account Managers know which technologies are available in the market and which technologies we are expert in. Their visits often bring us assignments. Internally, we bounce ideas off each other about which technologies and solutions are the most suitable for use. This is especially true if the customer is still in the orientation phase, as is the case with the customer we will visit today. In fact, it is particularly useful that I am there to share additional technical knowledge,” says Ivo.

Tuesday: develop technologies using proven project management

According to Ivo, “Different solutions were proposed during the meeting yesterday. Today, I will start to elaborate on these technologies. To do so, I follow our work processes to safeguard quality and eliminate risks. You can compare this to climbing a mountain: You can choose different routes to reach the top. However, if everyone chooses a different route and – halfway up – you look for the rest, you won’t know what the others are doing. If you discuss your choices before you start climbing, you can see what the others are up to and can quickly provide assistance when needed.”

Completing the customer case

In the first phase of the process, we identify the issue. What does the customer want to measure and why? “We ask the customer about their wishes and requirements. We then research feasibility on the technical and commercial fronts. We also estimate costs and risks. Then we record this information in the Project Initiation Document (PID),” explains Johan.

Johan continues: “Today, I attended an open-up meeting. This is where the Account Manager pitches the customer case to colleagues in the various departments. They often provide very valuable feedback. For example, our buyer indicated that a supplier is so busy that this may stretch the lead time. Critical questions can also be asked about the scheduled test setup. Suggestions on how to handle the issues will then be given. This input helps us complete the plan so the PID is then ready to be presented to the customer.”

Wednesday: product development and design

Even though we control all risks as optimally as possible, we sometimes receive a change request. Ivo relates that this occurred this morning: “Fortunately, it’s a small change. The customer wants a black connector instead of a white one. Even though the change seems to be simple from a technical perspective, I still call our buyer. During this discussion, I discovered that the change would require a longer delivery time and that the price is somewhat higher. I shared this information with our customer, who gave their go ahead. The project is now ready for the next phase.”

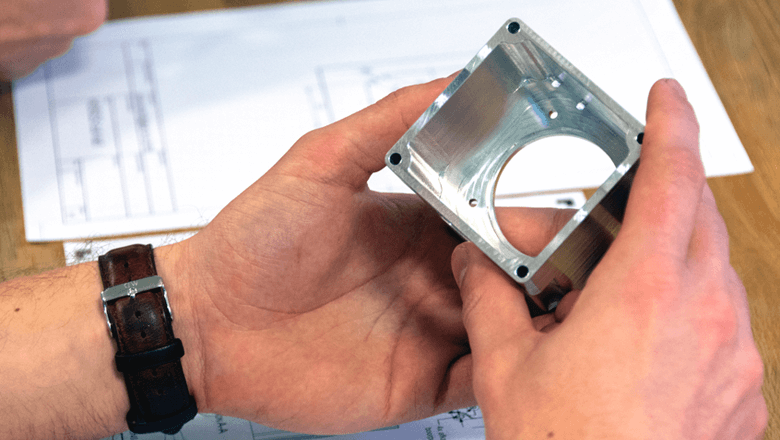

The second phase of our working method is all about product development and design. “Today, I am working on a different project. I check the project parts in detail so that the design and all of the documentation can be submitted to the customer. Once we receive the customer’s approval, we can start to build the first prototype next week,” according to Johan.

Our Senior Project Engineers Ivo and Johan work together to solve a sensor issue. Every detail is crucial.

Optimizing machines through engineering

Ivo uses the remainder of the day to work on an Agrifac assignment. One of this customer’s specialties is sprayer machinery for potatoes and beets. Ivo explains: “Previously, we developed a radar sensor to measure the ideal spray height. This technology records the tops of the plants. However, the customer now also wants to measure the distance to the ground.”

After a great deal of research and many tests, a German supplier of a radar module was found. “They modified their software for our needs, so we could achieve the desired accuracy. The samples were taken last year. We are now halfway through the third phase of the process – namely, making the prototypes reliable and ready for mass production.” Today Ivo is working with the production engineer on the test setup so that we can implement this in our internal production process.

Thursday: guiding the Production department

It’s written in bold letters in Ivo’s agenda – today, our Production department starts producing a new sensor solution. Ivo states, “I’m present so that I can answer any questions that may arise. The work instructions are complete so, at the most, it’ll just be about a few details. Besides analyzing the process, I will check the projected lead times – do our predictions agree with reality?”

Responding to trends

Today, Johan is attending a course on gluing. “We see a trend of a transition from using screws to using glue. This is especially true for new materials, such as carbon and 3D-printed plastic. As a designer, it’s to my advantage to keep up to date on this,” says Johan.

Friday: a sensor issue with a challenge

During the morning, we have a technical meeting at one of our large customers. Ivo explains, “In this intensive meeting, we discussed the development of an advanced load cell. We recently delivered two samples. Meanwhile, the customer carried out a residual gas analysis because the sensor solution will be used in a vacuum application. Even though the test result was positive, the accuracy must be further improved.”

Johan adds, “After thorough questioning, it appears that accuracy is not really the problem. The sensor is tiny, which impedes the read-out when it is installed deep in the machine. This is why it was difficult to match up the calibration data. Together, we discuss how we can resolve this issue.” Ivo comments, “Back at the office, we celebrate the start of the weekend with Friday afternoon drinks.”

Job vacancies in the high-tech

Only when we work together can we resolve sensor issues and deliver the best sensor solutions. Do you believe, just like we do, in the opportunities provided by technology? If so, you would be a good fit for our team! Our company is growing fast so we are regularly looking for new colleagues.

In addition to attractive terms of employment and an inspiring work environment, you will have plenty of freedom for personal growth.

Now is the time to check our open positions. Before you know it, they’re all gone.

This article was published in Mechatronica&Machinebouw nr.4 2019 and is written by Alexander Pil