3 important criteria optical and inductive encoders explained

A sensor that doesn’t work – it’s the nightmare of every engineer. Often this happens because the technology doesn’t fit well with the environmental factors. You can remedy this and even prevent it by identifying the important criteria of your application. The encoder specifications play a significant role here. At our stand at the 2019 Precision Fair, we compared inductive and optical encoders using a demo.

The Precision Fair is the premier annual knowledge and networking event for precision technology. More than 300 exhibitors were present at the fair, which was organized by the Mikrocentrum. A record number of attendees was achieved by 3700 visitors from 42 countries.

When comparing encoders, our sensor experts discussed environmental factors such as contamination, vacuum and light weight. Visitors also learned more about inductive encoders during the technology lecture given by POSIC. Further on this page, you can download the trade fair presentation.

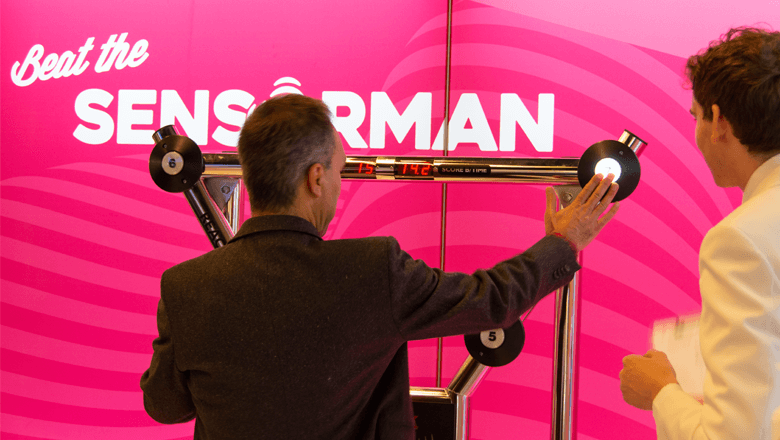

Our booth visitors also took their turns beating the Sensor Man in the Sensor Challenge. Enjoy the Fair photos. You’ll find them at the end of this article.

To arrive at the most suitable encoder system, you must first know what you really need. Our 10 questions will help you do this.

Important selection criteria for encoders

Encoder systems differ based on their specifications. These properties determine how well the sensor works under certain conditions. The decisive factors are contamination and vacuum environments. In certain applications, however, the weight of the encoder can determine the choice.

1. Contamination

How dirty or clean is the environment of your application? For example, inductive encoders work perfectly when the scale is full of dust or grease. Optical encoders, however, are much more precise, to 1.2 nm. But they are sensitive to contamination.

2. Vacuum

The use of encoders in vacuum environments can lead to surprises. “There is no air for cooling. This means that certain types of sensors can become overheated. You may also have to deal with outgassing,” according to Sean Ram, Account Manager at Sentech. There are solutions for both factors. This naturally depends on the system requirements. For example, optical encoders use little electricity so they barely become hot, even in a vacuum environment.

3. Weight

If your application must be lightweight then your technologies must be, too. This may occur, for example, if you have a machine that makes quick movements. Nowadays, encoder systems that weigh less than 5 grams are available.

Collaboration with POSIC

Our speaker, Sietse Wouters, is a co-founder of POSIC. He received his doctoral degree in microelectronics at Delft University of Technology. During the technology lecture, Wouters talked about the development and technical aspects of inductive encoders.

The technology used by POSIC is focused entirely on inductive encoders. The coils of their encoders are integrated with the electronics in one single silicon chip. This makes their products unique. This is also the reason that Sentech often selects the inductive systems of this supplier.

How do you ensure an optimal encoder integration?

Using these 3 important selection criteria, you will obtain insight into the possible problem areas. There are also multiple factors that are important. Our infographic helps you go through the 10 criteria for optimal encoder integration.

We also share POSIC’s Precision Fair presentation as a PDF (2.2 MB).

Discover the ins and outs of the technology of inductive encoders.

Fair photos