5 sensor technologies applied in the agricultural sector

Smart farming and precision agriculture, where technology is used to provide crops and animals with the precise treatment they need, are terms that you hear popping up in conversation more and more. This is not at all surprising, given the looming food shortage and the growing world population. An increasing number of companies in the agricultural sector are implementing new developments to meet the rising demand for food while requiring less manual labor. Machines with innovative sensors are indispensable for this. This article describes the 5 most important sensor technologies that have been successfully applied in the agricultural sector.

These developments in the agricultural sector have prompted many OEMs to look for an end product that can be integrated directly, is watertight and that can withstand heavy contamination. Good to know: all of these sensor technologies meet those requirements!

Sensor technology 1: load cells and force sensors

Load cells can measure weight – anywhere from a few grams to several tons. These can also be found in your bathroom scale at home. The most commonly used load cells work with a strain gage on a metal body. As it bends, this metal body translates the force to be measured to the strain gage and to an electrical signal that is then converted to the weight reading. This is useful for a machine or application where weight is an important factor and where you want to measure directly during the process.

For example, let's say you have a fertilizer cart and want to know how much fertilizer you have left before the cart is empty. Or if you want to know how many beets you have already harvested. A load cell can supply this information by measuring the weight. Or with a plow, you can measure the resistance level of the machine to prevent overloading. In short: you can measure weight and force in order to check whether the entire process is running according to the right specifications. And no less important: load cells are highly resistant to contamination and can be applied in some of the harshest conditions.

Using this sensor technology makes machines, vehicles and equipment smarter and enables cost-effective production processes at agricultural companies. There is, however, one issue to consider: load cells are actually not that simple to implement. It requires a fair amount of integration knowledge and expertise.

Sensor technology 2: lidar

A lidar sensor is an optical measurement system with an infrared laser that scans, maps and detects objects in the environment. Lidar shows the distance to objects and possibly says something about the shape. Of a vehicle, for example. How does it work? It is based on the time of flight principle. That means that the sensor is able to measure the time difference between when a light pulse is transmitted and when the reflection is received on an object.

This time difference multiplied by the speed of light, and divided by two equals the distance to the object. And that certainly comes in handy, because if a vehicle is going to drive automatically, you need to make sure that no trees are in the way and no cows are walking past. In fact, with autonomous driving, you are replacing the human senses, of which our sight is one of the most important. Our eyes can perceive images, identify shapes and gage distances. The lidar sensor takes over distance measurement in particular. What's the advantage? By using infrared light, lidar actually has better vision than the human eye. Especially in the rain and fog!

In addition, this sensor can be equipped with a 360-degree viewing angle and it never gets tired. In short: lidar delivers precise and absolute depth perception, requires less manual labor and works quickly and consistently. It ensures that your machine works accurately no matter the circumstances and can do the exact same thing a million times in a row whenever necessary.

Sensor technology 3: internet of things

Internet of Things (IoT) refers to the (wireless) connection of physical devices to the internet. The internet has become an integral part of our lives and is playing an increasingly important role, also in the agricultural sector.

It is important for agricultural businesses to be able to plan and make decisions for the future based on information that has been gathered. For example, by using temperature sensors, humidity sensors and distance sensors, you can collect data from crops or livestock in the cloud and analyze these. These analyses will bring up questions such as the following: What am I going to do next year? More or less fattening, more or less feeding, at what times, in what weather conditions? And not to mention: How often has my machine been out in the field? How much time have I spent in a particular area? Can it get done faster? This allows farmers to make increasingly smart decisions and improve their production step by step.

With artificial intelligence (AI) and machine learning, you can even work on the preventative maintenance of machines. Sensors placed in critical locations in the machines collect data. These data are then analyzed. As machines begin to recognize certain signals that indicate a malfunction before it occurs, maintenance can be performed in a more timely manner. This prevents costly and unplanned downtime!

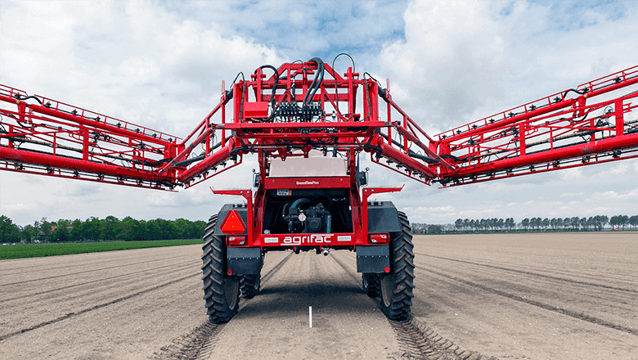

Sensor technology 4: position and level sensors

Position and level sensors are widely used in the agricultural sector. For instance, level sensors allow you to measure the contents of tanks and to optimize work processes. This can be done using an ultrasonic sensor or a pressure measurement. Let's say a farmer goes out into the field with a machine to spray a crop. In that case, it's helpful to know how much liquid he's carrying and when he needs to go back and fill up again. Only finding out halfway across the field that the tank is empty, and having to drive back unnecessarily several times and then not remembering exactly where he left off can cost him a lot of valuable time. What a waste!

Position sensors monitor and control the correct position and height of the equipment above the crop. Some examples include ultrasonic sensors, linear or rotary hall effect sensors or encoders. Depending on the circumstances, laser, LiDAR or radar sensors could also be suitable solutions here. No matter which option you use, it will help you work much more accurately. It is certainly safe to say that position and level sensors make machines a lot smarter, allowing farmers to work more quickly and efficiently.

Sensor technology 5: distance sensors

You can use laser or ultrasonic technology to measure distances. However, the first alternative is more sensitive to dust and the second to wind, factors that make them less suitable for the agricultural sector. With a radar, you don't have any issues with pollution or wind, making this distance measurement solution ideal for farmers. Radar sensors also work on the time of flight principle, but instead of light or sound, they use very high frequency radio signals in the GHz band.

The various high frequencies all have unique properties. For example, radio waves have very high penetration capabilities and not only see the top of crops, but also the different layers of leaves as well as the soil. In other words, this actually lets you see through the crops! Radio waves can also measure unobstructed distances from buildings, objects, or solid and liquid substances. That makes this distance sensor suitable for applications such as fluid level measurements, distance measurements and object detection.

Due to the increasing demand in the automotive industry, the cost of basic radar sensors is decreasing. Coupled with their favorable properties, this ensures that these distance sensors are being used increasingly often in agriculture. This is an ideal solution, as it allows farmers to define distances very accurately without the sensor being affected by contamination or wind.

Evidence from sensor technologies in practice

It all sounds good on paper, but how do these sensors work in reality? In wind and rain? The fact is that heavy machinery and large agricultural vehicles have to continue operating reliably in harsh and fluctuating conditions. This is why proper integration including cabling, housing and mounting materials is essential for sensors. As an OEM, you want an end product that can be integrated immediately, that is watertight and that can withstand significant contamination. That is exactly what the sensor solutions from Sentech provide.

Are you looking for the smartest technologies for your machine and want customized advice? Then turn to a specialist. You can read why this always pays off in the end here. At Sentech, we have years of experience in this sector and are happy to work with you to find the ideal solution.