How robots will become the surgeons of the future

Robotic surgery is here to stay. Drawing inspiration from Intuitive's renowned Da Vinci surgical robot, a thriving industry has emerged dedicated to the advancement of robotic systems for operating rooms and healthcare facilities. Cambridge Medical Robotics, a prominent player in the field, secured an impressive USD 600 million in an investment round two years ago to propel the ongoing development of its Versius surgical robot.' A lot of money is also being pumped into Medtronic's comparable Hugo system.

That capital is very much needed, says Stefano Stramigioli, Italian-born professor of Advanced Robotics at the University of Twente. 'It's great that we've trained a smart computer to play Go, but when it comes to surpassing the dexterity of a human hand, we still have a long way to go. It doesn’t exist, and won't be happening anytime soon either'.

Homunculus

To illustrate the complexity of the human hand, Stramigioli refers to the neuroscience concept of the motor homunculus, where each motor movement in the human body corresponds to a specific area in the brain. Interestingly, our hands occupy a disproportionately large portion of this brain map. If this was represented based on senses, the hands would once again stand out, together with the mouth, eyes, ears and nose, of course.

It therefore comes as no surprise to Stramigioli that a company like Boston Dynamics can post all kinds of fascinating videos about the incredible movements their robots can perform, but that the 'hands' of these systems are merely rudimentary stubs. It’s true that robots exist which can play table tennis, but try finding a robot which can make a bed. Or even more challenging; perform a very precise surgical operation. 'Do something subtle with an unknown object with a robot hand? Forget it,' says the Twente professor.

Challenging physical interaction

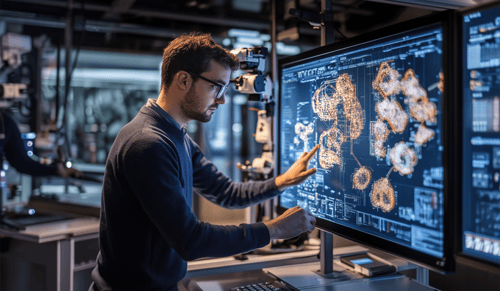

The primary challenge for Stramigioli and his fellow researchers at the UT lies in the realm of physical interaction, which is at the core of surgical procedures. 'Surgery is all about that physical interaction,' he explains, highlighting the complexity of the issue. 'While diagnostics rely heavily on data, such as the utilization of algorithms and data analysis in radiology, surgery presents an entirely different scenario due to its intricate interactions.'

Stramigioli looks beyond conventional robot solutions like Da Vinci, Versius, and Hugo. 'I believe that standard robotics, in which the capabilities of humans – which, incidentally, are long from being replaceable due to the complexity of the situation – are linked to the advantages of robots that can work more precisely and with which you can filter out vibrations. That concept of a system which can be remotely controlled with rigid instruments certainly has a future,' thinks Stramigioli, but personally he prefers to look at other solutions.

Flexible robot

Stramigioli emphasizes four significant goals that drive medical robotics research at the UT. The first is training. 'Surgeons must be proficient in using these tools. However, existing simulators designed for surgeon training are highly intricate and expensive, limiting their widespread availability,' says Stramigioli. To address this, UT researchers are developing an accessible training system for surgeons to practice with an endoscope. 'It’s almost serious gaming; you can connect it to your home TV and practice.'

Moving on to minimally invasive surgery, Stramigioli points out the paradigm shift. 'They used to say, “major surgery, major cuts”, but that mindset has completely changed. The less invasive the procedure, the better," he explains. Consequently, these days a growing number of laparoscopic operations are performed using small incisions for instrument insertion.

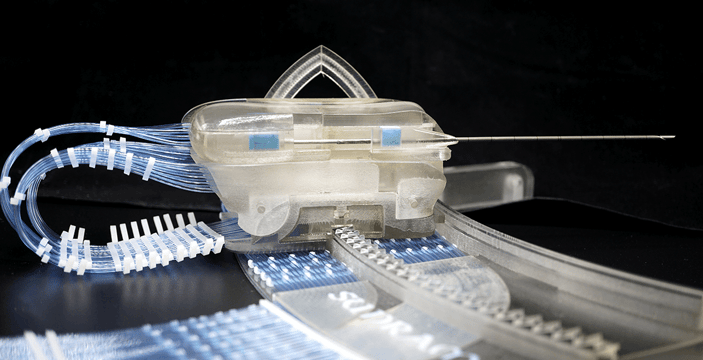

Stramigioli also highlights alternative approaches, such as endoluminal procedures, where instruments are inserted through natural body channels like the esophagus or intestinal tract. ‘To facilitate these techniques, flexible robot solutions like the Teleflex system have been developed, enabling movement in harmony with the surrounding environment. This flexibility proves highly valuable in fields like oncology.’

MRI-compatible drive solutions

Pneumatic actuation system

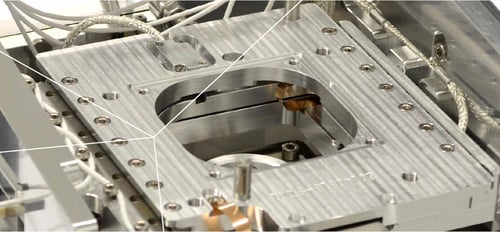

The third pillar of medical intervention is interventional radiology. Doctors have various options, such as CT scans, X-rays, and MRI, to internally examine patients. Among these techniques, MRI is preferred due to its non-ionizing nature, which offers numerous benefits to the patient. However, working with a strong magnetic field poses a challenge for MRI, and standard robot technology with all its metal components cannot be utilized.

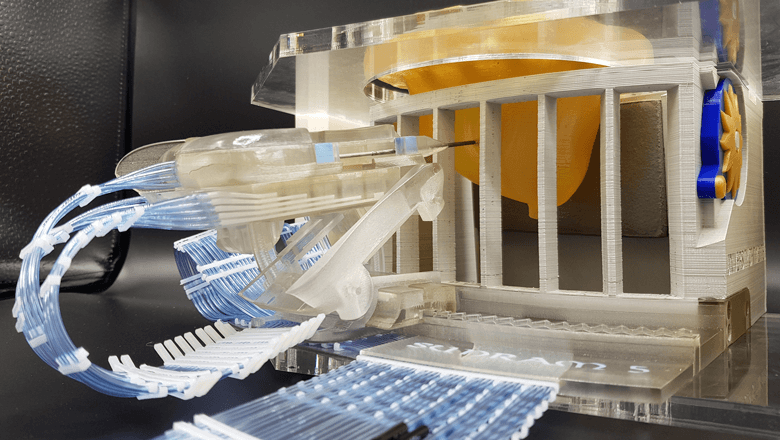

To address this, researchers at the UT have come up with a solution. 'We’ve developed a patented actuation system that works completely pneumatically,' says Stramigioli. This technology is currently focused on breast oncology and is being refined in collaboration with Machnet Medical Robotics. The system enables remote control of a needle controlled by an MRI-compatible drive.

This advancement could bring about a significant change in breast cancer treatment,’ says Stramigioli. ‘You can steer a needle very accurately to the location of the tumor because you can continuously see where you left off. You can then kill the cells from the head of the needle, for example with a laser or extreme cold. Once the cancer cells have been eradicated, the needle can be safely withdrawn, completing the procedure.'

Clinical tests

Stramigioli has even bigger plans: ‘I have a vision where a woman who isn’t even aware she has breast cancer can enter a hospital and leave completely cured within a few hours. It may sound like science fiction, but it isn't. There are already methods available to analyze tissue by puncturing it with a needle, allowing us to determine if a tumor is malignant. Moreover, using the same fiber, we can use a laser to ablate the cells.’

The MRI-compatible drive is currently being prepared for the market through Machnet, with initial funding from Canada. The first clinical trials are scheduled to commence soon. ‘We hope to launch it within a few years,’ adds Stramigioli. 'We then also want to make a similar solution for endovascular procedures, as navigating a catheter through a vein requires the same propulsion concept.

3D printed sensors

The fourth important factor in the Twente research program on medical robots revolves around intelligent materials, specifically the combination of additive manufacturing and conductive materials. 'If you dip the printing material with these conductive materials, you can print sensors,' says Stramigioli. That is beneficial for patient-specific prostheses, for example. 'With the aid of MRI, you first make an image so that you have accurate information about the patient available and you can print a custom prosthesis. You can incorporate a force sensor in the print to register the load on the prosthesis.”

This technology is still in its early stages, but Stramigioli already sees significant potential. “The main thing at the moment is for a company to take it seriously. Then we can really get to work on a roadmap.”

Location sensors

When asked about the sensor technology required for his research projects, Stramigioli mentions advanced location tracking solutions. 'There’s more and more imaging in drones, because cameras and computing power are virtually free these days.'

He talks about the Canadian NDI that has developed a kind of GPS technology for the body. A small EM microsensor can determine its location in the body based on an external electromagnetic field. 'These sensors can be placed in needles or endoscopes for navigation,' says Stramigioli. 'Any sensor that helps determine the position is useful. If was also MRI compatible, that really would be a massive breakthrough.'

How are medical devices developed?

As the world's population grows, medical devices are advancing at incredible speed. An original equipment manufacturer (OEM) of medical devices has more options available than ever before. However, this is associated with various challenges, and there are other factors to consider too. How can you create the ideal product with a reliable quality that is affordable to produce?

This e-book contains useful information about the 5 main challenges for developing medical devices and the role of sensor technology.

.png)