Vacuum sensor solution in unique microscope

Using sensors to optimize your medical device. How do you go about this kind of sensor integration? Knowledge of sensor technologies is essential here. That is the only way to guarantee quality.

This blog features a real case study of successful sensor integration in a medical device.

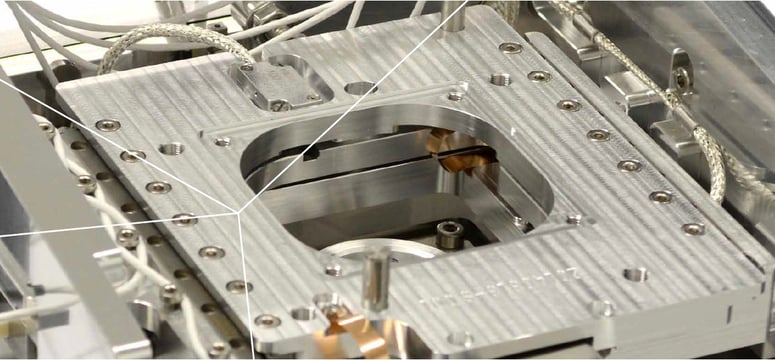

The manufacturer Delmic was looking for a reliable sensor solution for positioning a sample in a vacuum chamber. How did they address challenges such as: accuracy, vacuum conditions and the limited installation space?

Unique device

Equipped with a vacuum sensor from Sentech, Delmic's SECOM is conquering the international microscopy world. It is the only device in the world that combines fluorescence and electron microscopy in a single integrated setup. The unique microscope is compatible with all types of SEM electron microscopes.

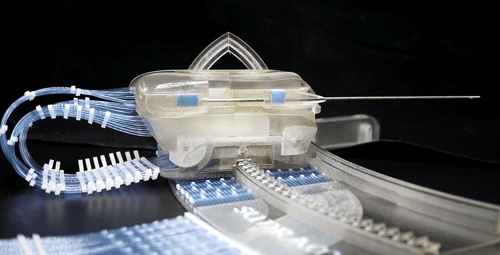

Sentech has developed a vacuum resistant optical encoder solution for positioning a sample in the vacuum space. The independent sensor integrator provides the solution as a sensor assembly, enabling Delmic to assemble it easily in the SECOM.

At Delmic, roughly a dozen people worked on the development and manufacture of high-quality microscopy technology. With products such as SPARC, its portfolio offers solutions for materials research. And with SECOM, it provides solutions for biomedical research.

The correlative light and electron microscope (CLEM) can be integrated as a module into virtually any scanning electron microscope (SEM), also known as a grid electron microscope.

Benefits of CLEM for medical science:

- Ease of use

Researchers no longer need to produce two images from separate devices and then process them using software. - New research opportunities

Short-life samples can be examined as it only takes 1 minute to produce an image of a sample. - Technical image quality

The images offer an incredible level of detail that cannot be achieved with other devices. - Time savings

For those occasions where research time is limited, the system saves a huge amount of time. The short operating time of the machine makes it possible to carry out population research quickly, for example.

Vacuum sensor development for the vacuum space

SECOM owes its extreme accuracy and high resolution to a unique optical vacuum sensor. Sentech supplies the customized MicroE optical sensors in a fully tested and calibrated assembly. For each CLEM system, Delmic receives three sensor assemblies – one for each axis of motion – which can be assembled quickly and easily.

Conquering the world with reliable sensors

According to Delmic, its satisfaction with Sentech was not only a product of the pleasant cooperation in an open development environment. "SECOM has been on the market since 2013. To date, all of the sensors have been working flawlessly. The promised specifications and performance levels have been fulfilled."

The SECOM platform has proven its value and is slowly but surely conquering the microscopy world.

Would you also like to conquer the world with innovative sensor technology?

Read more case stories in our ebook 3 examples of sensor solutions in medical devices.