Coping with the scarcity of raw materials in manufacturing

The scarcity of raw materials is hitting the manufacturing industry hard. This makes your job as a purchaser challenging, especially when dealing with OEMs and machine builders that have long supply chains. You have to prevent, at all costs, deliveries of your end product from being delayed because a single component is missing, so how do you cope with these material shortages?

Being aware of how you can exert influence as a purchaser helps. We share some useful tips in this article.

Long supply chain

Buyers in manufacturing know better than anyone that a long supply chain increases the risk of delays. We’ve all heard the stories about brand-new trucks parked on a site somewhere which can’t be delivered because one small part is missing. These are clear examples of the scarcity of raw materials.

The supply chains in some sectors, such as the semiconductor market, are stuck in a vicious circle. What does that mean? That the finished products are necessary to make the raw materials for the end product. One good example of this is chip machines. Chips are needed to make such a machine; the very chips produced by the machine.

If our end customer needs products to supply the raw material producer, monitoring continuity is even more important. Escalation meetings with suppliers are particularly important in these types of projects.

Why is there a scarcity of material?

Back to basics for a minute. What are the reasons behind the material shortages? Buyers purchase goods worldwide, in other words goods are produced at various locations. The raw materials also have to be transported to these locations.

During the COVID-19 pandemic, huge queues of ships were waiting in the ports. They’re unable to unload, which threw the entire shipping planning upside down. It puts a massive brake on raw material supplies.

7 tips on dealing with a scarcity of raw materials

If you hold some stock, you don’t simply run out of components as soon as a material shortage arises. But these stocks are never unlimited. After escalation meetings with your supplier, sometimes the best course is to think outside the box. What’s the smart way to deal with a scarcity of raw materials?

1. Cooperation with R&D

Work closely with your colleagues from R&D, as they often know what they’re talking about when it comes to components. And if they’re not sure, they find out from the supplier. That's where you can gain an advantage.

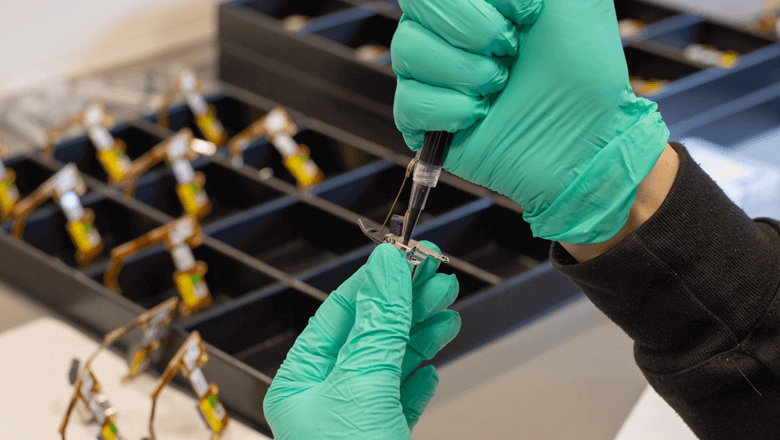

Conversely, you can also help your R&D colleagues with your purchasing expertise. Our R&D department came up with a great plan, but there was one big problem: some of the components weren’t going to be available for more than a year, and the customer wanted to receive the sensor solution within six months. I provided a list of alternative components, which were available. R&D studied their suitability. The result? The lead time was shortened by a year!

2. Know the strengths of your suppliers

You can use your role as a purchaser to influence the type of supplier you choose. If you know what your suppliers are good at, you can make a careful selection that will affect prices and delivery times.

Let’s look at the metal industry. Some suppliers are specialists and work accurately, while others are less focused on accuracy but produce in series. It’s important to know which supplier is good at what, so you select the most appropriate one when you need something.

If the one supplier is a specialist in something but you just need simple serial processing, it's better to use a different supplier. Then the price and delivery time are more in balance with what you need.

3. Specify your components

The more detailed the specifications your components have to meet, the faster you find yourself in a jam. However, if you put in your specifications 'it needs an M4 screw', there are plenty of options available. When you develop a product, you have to think about this aspect. It starts with the basics. What materials are the components you select made of? What risks are they associated with?

Avoid being brand-specific wherever possible, unless it’s necessary for the functionality. That's why it's so important to talk to your R&D department. You have to know what's important, what’s really needed. Imagine; I need a small panel. What does that small panel have to do? Does it have to contain metal for the magnetism? Or do you need a tolerance, range or very specific material that makes it repellent to something?

You have to know what the customer, and therefore the application, needs. The appropriate quality is also important, to prevent disruptions in production. That’s certainly the case in robotics applications where everything has to be extremely accurate. A cheap product is a bad idea in this situation, because the risk of disruptions in the production process where such a robot arm is used are way too high.

Basically: if you accurately specify what you really need, you keep your price and delivery time optimal. That’s how you make the difference as a buyer.

4. Acquire more knowledge at component level

If you look closely at datasheets, certain items are from the same manufacturer. For example, an improved version of the same product, or the same product made from a different material. This requires knowledge about components. Talk to your R&D colleagues and your suppliers about components. Then you will be better informed and able to purchase components more flexibly and efficiently. This ultimately increases your influence on a predictable supply chain.

5. Set priorities

Once you know the priorities, you can come up with targeted solutions. So, how do you determine those priorities? You have to talk to your customer. This is one of the last resorts, because you want to facilitate your customer. We therefore ask our customers, 'When does your production threaten to come to a standstill?' We want to prevent that at all costs, so we identify what the customer has in stock and what our options are. That is then converted into a schedule, which is used as the basis for discussions with the supplier.

6. Know what a component is made of

It’s worth looking beyond 'which components are scarce'." Think about the parts the components are made of, and which parts are scarce and cause long delivery times.

Sometimes various components that you purchase contain the same scarce part. If the supplier receives this difficult-to-source part, they first have to incorporate it into the component that is most needed. Then it’s placed in the next most important component. We make agreements about this. Make sure your suppliers know your priorities. Once again, this shows how important communication is.

7. Relationship management with suppliers

Building a good relationship with your suppliers pays off in the long run. Visits to suppliers are an opportunity to have a look behind the scenes. You also quickly understand the areas in which you can exercise leverage.

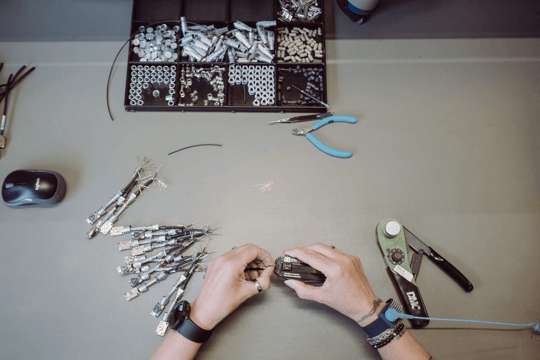

Our purchaser visits suppliers with an R&D colleague. The R&D colleague looks at things from a technical perspective: what are they able to do? As a purchaser, on the other hand, you look at the commercial side of things: what are their lead times, what are their prices, and what kind of request will give me the best quote?

Which ships arrive or don't arrive is beyond my control, but I can make a difference by letting people know 'I need this' in good time. A supplier can then anticipate events beforehand, and make sure its stock is in order.

Innovation through alternative components

Sometimes when components aren’t available, it can force innovation. Imagine… A sensor solution design was developed 15 years ago. If an end-of-life is announced for a component after this period, you have to find an alternative.

The technology that existed 15 years ago is probably outdated by now. It’s also possible that the application has changed. For this reason, we always talk to the customer about whether the solution still meets their needs. It may well be an appropriate moment to develop a new product. This is how alternative components promote innovation.

How do you get better control on your supply chain?

That’s the end of our tips and tricks for dealing with material shortages. However, this is only part of your purchasing strategy, because as a buyer you can influence your supply chain in many other areas.

Our free e-book explains many other methods to keep your supply chain running predictably. These are based on practical examples.

Download the e-book right away and get some inspiration.