5 tips to limit purchasing risks

Purchasing risks are an inherent part of your job as a buyer. For example, rising purchasing costs and longer delivery times can put your project in jeopardy. A lack of expertise at component level can also hinder your decision-making. How do you effectively manage these uncertainties in the supply chain?

One thing is certain; you can do something to reduce these risks. We’ve listed 5 useful tips for you. Inspire yourself, and enrich your skills as a buyer.

1. Supplier management

As a buyer, you want the goods you order to arrive on time. What’s the best approach to prevent suppliers from delivering too late? You need to know how our partners score in terms of delivery reliability. Our ERP system can measure and track how many of our purchase orders were delivered correctly.

We periodically share these scores with our suppliers. This is an opportunity to enter into dialogue with them and encourage them to increase delivery reliability. The manufacturer also gains insight into how we, as a customer, view their performance during that period. It’s a useful moment to discuss forecasts and agree on delivery times and stocks.

2. Quality assurance

Quality assurance is a much-discussed theme in the supply chain. How do you ensure that the finished product meets requirements?

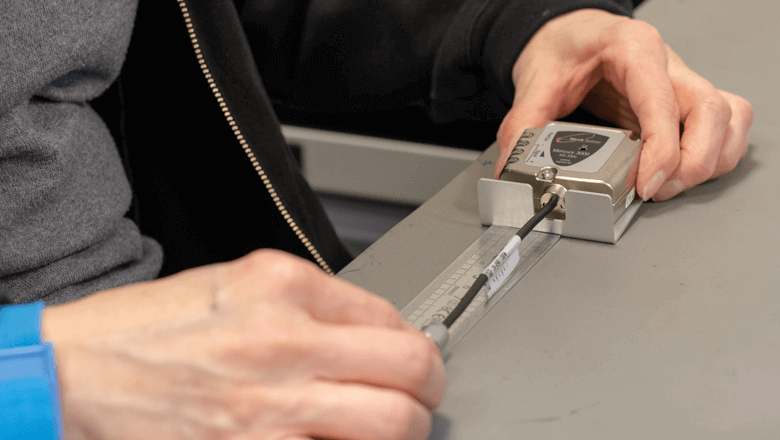

We check all incoming goods. We look at aspects such as whether the item is of the correct length and color. After the sensor solution has been assembled, we obviously want to be sure that it meets the set quality standards. Our test engineers test our sensor solutions with special equipment.

The later in the chain you carry out checks, the greater the financial consequences of any quality issues. That’s why the most efficient approach is for suppliers to check their goods before shipping them. It pays to make agreements about this with your suppliers.

Quality awareness

The Quality Department makes everyone at Sentech aware of the importance of quality. Quality Assurance Is at the core of our work processes. By following the prescribed steps in a process, we identify and eliminate risks. This allows problems to be discovered at an earlier stage in the process, rather than too late.

Assembly engineer checks length of incoming components with a special test rig.

3. How to respond to increasing delivery times

Long and increasing delivery times can jeopardize an entire project. If the customer wants to receive a finished product promptly, you as a buyer can find yourself facing an uphill challenge. How should you act in such a situation?

Our sensor solutions often contain custom components which manufacturers develop especially for us. If a component is being made for the first time, the delivery time can be particularly long due to the R&D that precedes it. A product is monitored and improved through its development, to guarantee quality.

Shorten delivery times

There are some tricks to shorten the delivery times of both off-the-shelf and custom components. If delivery times begin to creep up, we often ask that an order is sent in partial deliveries. Our production department can then assemble a first batch of sensor solutions straight away. This is a short-term solution. As a long-term solution, flexible forecasting is a useful tool to shorten delivery times. We share our forecasts for the year ahead with our suppliers so they can take this into account when planning production.

Purchase pattern per sector

Building a stock is one way of dealing with rising delivery times, but on the other side, as every buyer knows, it’s best to limit components held in stock. How to find a good middle ground? Ideally, we use just-in-time deliveries to avoid holding stocks. Unfortunately, it doesn't work that way in practice. It’s important to find the right balance between meeting delivery deadlines and the costs of holding stock.

Increasing your stock is always risky. There’s always a danger of materials becoming obsolete or move rates collapsing. Those are major risks. If you’re facing long delivery times, you can increase your stock as a buffer against fluctuations. How risky it is to hold stock also varies from sector to sector. For example, purchasing patterns in the automotive sector are very stable.

It pays to find out more about the purchasing patterns of the sectors in which your customer base operates. Holding stock entails outlay in three distinct areas, namely interest, space, and risk. The exact costs in each area depend on the type of product. The purchasing department is responsible for minimizing the total cost of ownership, in combination with fulfilling all our promises to the customer in terms of what we supply.

4. Prevent rising purchasing costs

Rising prices can put you in a difficult position as a buyer. You want to know what to expect, so how do you exert influence in such a situation?

When developing a new product, you have to deal with R&D costs. Your product price depends on this. Have these costs already been paid off, or are they incorporated in the price of the product?

In practice, we often see that development costs are incorporated in the cost of the product. As a buyer, you can’t do much about this. Nevertheless, it’s important to know the strategy of your suppliers in this respect. If you’re not clear what’s happening with these costs, you can’t have any insight into future price changes. For example, you might expect that the price can be lowered, because you’ve assumed that the R&D costs have already been written off. But how do you know? That’s why it’s so important to make long-term agreements on this.

In addition to recording agreements on R&D costs in contracts, it’s also a good idea to clearly formulate the justification for any price movements. Such as with components that contain a lot of steel. In that case, I recommend linking product prices to steel prices. Make clear agreements on this with your suppliers.

5. Bundling technological expertise

As a buyer, your knowledge about the details of components may well be limited. That's almost certainly the case when it comes to high-tech components. How do you assess your supplier's expertise if your own knowledge of a subject is limited?

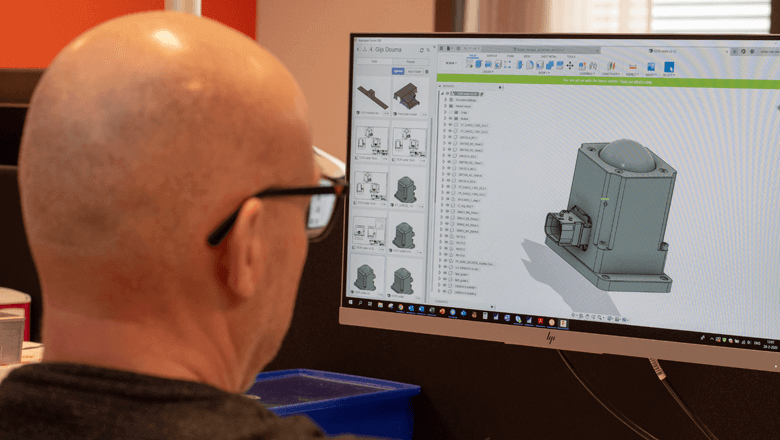

Work in a multidisciplinary team

It’s important that a supplier has in-house expertise, especially when it comes to custom products. We set up a multidisciplinary team for such projects. In addition to myself as purchaser, our RD&E department and an account manager are also members. This gives the team the specialist knowledge needed at component level.

With the help of the multidisciplinary team, we carefully select the components and supplier. We choose our suppliers carefully on the basis of quality, logistics, technics and costs, not just according to their technological expertise and experience. Delivery reliability is another key factor. After being selected, the supplier is also involved in the project as a source of knowledge.

Create your own predictable supply chain

The above 5 tips will help you eliminate purchasing risks, bringing you a big step closer to a predictable logistics chain. However, there are many more aspects you have to consider, such as how to deal with inventory management.

Read more about this in our free e-book, which contains practical examples from the world of sensor technology.

Stay informed. Download the e-book, and take advantage of a wealth of tips and tricks.